- Home

- Company

VSM - MORE THAN JUST THREE LETTERS

Our knowledge of abrasives is second to none – and has been for over 160 years. Perfect surface quality, high stock removal, long service life – and all this while maintaining consistently outstanding performance. These are the distinctive features that continue to impress customers of VSM abrasives all over the world.

- Navigation

- The story behind our name

- Discover VSM

- Certified

- Milestones

About VSM

VSM – More than just three letters

Our understanding of abrasive processes is second to none. Not only do we grind every surface to a high-precision finish, we also analyze our customers’ specific grinding applications to ensure we always find an optimum long-term solution.

Application-specific know-how is a key differentiator for VSM, and is highly valued by industry, trade and retail customers all over the world.

Expertise. Quality. Customer focus. This is what VSM stands for.

Our day-to-day strategy and decision-making is shaped by our company values.

VSM Abrasives Corporation USA

As new products are developed in Hanover, Germany, they are shipped to international subsidiaries in the form of jumbo material. These manufacturing facilities then convert the material into the final product form based on end user specifications.

In 1978, the subsidiary known as VSM Abrasives Corporation was established to meet a growing demand for coated abrasives in the United States. Just outside St. Louis, Missouri, this location offers manufacturing, customer service and technical support to customers across the country. And, with over 7,000 rolls of jumbo material on-hand, customer requests can be processed quickly.

The story behind our name

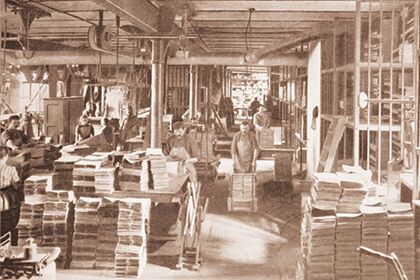

How do the terms Vereinigte Schmirgel- und Maschinen-Fabriken AG come into our company name? It’s quite simple: The company was launched on 28 May 1864 with the foundation of S. Oppenheim & Co. in Hanover, Germany. We began initially with the small-scale production of glass and flint paper, i.e. by hand.

As the requirements of grinding performance increased rapidly as industrialisation progressed, the company began to rely on emery as a new material from the end of the 19th century. The hard rock, mined on the Greek island of Naxos, wore out less quickly than glass, but nevertheless provided very high grinding performance and quickly became our company’s most important raw material. Emery has even become so important that its enormous significance is still reflected in the company name today, even though emery is no longer used as an abrasive grain.

As early as the 1880s, VSM augmented its portfolio with the construction of machines: Suitable grinding machines were developed and manufactured in the machine factory, as were hydraulic forming and casting machines, sandblasting blowers and melting furnaces, which were successfully sold to the booming industry. Machine production was only discontinued with the major global economic crisis in 1929/1930. Since then, VSM has focused entirely on the production of coated abrasives.

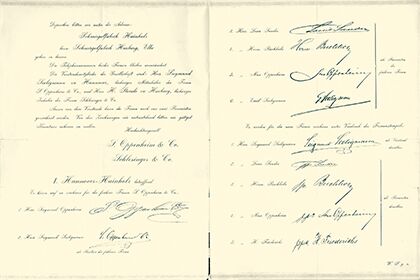

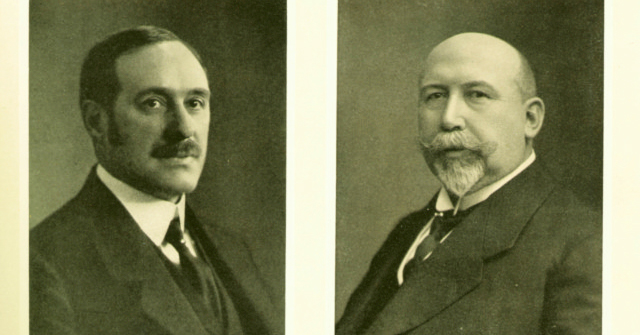

In September 1898, S. Oppenheim & Co. teamed up with Hainholz with Schlesinger & Co. Harburg, another major abrasives manufacturer and then competitor, to form the Vereinigte Schmirgel- und Maschinen-Fabriken Aktiengesellschaft. We still bear this name today.

We are VSM · Vereinigte Schmirgel- und Maschinen-Fabriken AG

Discover VSM

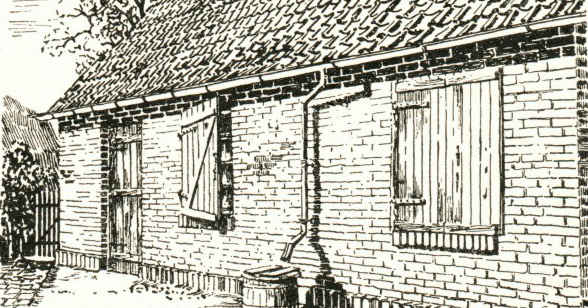

Business start-up

On May 28th, 1864, Siegmund Oppenheim and his technically skilled brother-in-law Siegmund Seeligmann laid the foundations of what was later to become VSM. The company named S. Oppenheim & Co. began working in small production rooms in Hanover-Hainholz. More than 160 years later, VSM's headquarters and production is still at this location. While the company started operations in open countryside in 1864, the city has meanwhile grown around the plant.

The stag beetle trademark

Walk carefully through the VSM company premises today and you will see it over and over again: The stag beetle. In 1875 it was registered as a trademark by the company S. Oppenheim & Co. Back then, trademark protection law allowed trademarks to be registered with the District Court. The founding fathers of what later became VSM recognised the value of a memorable logo at an early stage. For this reason, they registered the stag beetle as a trademark.

Oldest plant fire brigade in Lower Saxony

One of the greatest dangers for a manufacturing company has always been fire. Like many other companies, VSM therefore has its own fire brigade. Ours was founded on July 1st, 1880 by the company founders Oppenheim and Seeligmann, making it one of the oldest fire brigades in Lower Saxony and Germany. At the beginning it consisted of 14 employees and this number continued to grow steadily in the following years, to...

The invention of wallpaper paste

What do discoloured wallpapers, a former VSM apprentice and the adhesion of the emery to the backing have in common? They all led to the invention of wallpaper paste. During his apprenticeship at VSM, Ferdinand Sichel became aware of the complex processing of animal adhesives and bonding agents in the production of abrasives. He was already well aware of this problem from his parents’ company, a company for wallpaper and chalk paints.

Specialisation in coated abrasives

Our motto: Stay flexible at all times! After ceasing machine production as part of the global economic crisis, from 1929-30, VSM concentrated exclusively on the production of coated abrasives. A new finishing plant played a significant role at this time, as it was able to significantly increase product quality from 1932 onwards. This allowed cloths to be specially designed for use as backings for flexible abrasives. At this time, these were referred to in Germany as Schleifleinen (abrasive linens)...

VSM goes international

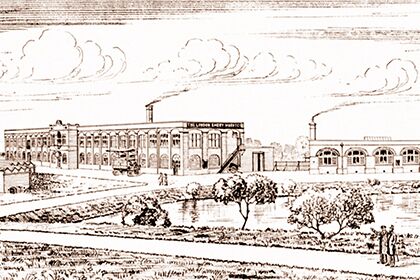

VSM’s high-quality abrasives attracted the attention of the industry in neighbouring countries at an early stage. As early as the 1890s, for example, VSM had an eye on the highly interesting English market and built a factory there based on the Hainholz model. In fact, the company was very successful in Great Britain with its own English brand “Atlas”. In 1918, as a result of the First World War, the factory was lost. But at the turn of the century, business was already booming in the rest of Europe...

In-house ceramic grain production since 2004

Hard-wearing: Our in-house developed and produced ceramic grain. The world of abrasives is always on the lookout for the best abrasive grain for specific applications. And when it comes to high stock removal, ceramic abrasive grains are clearly the first choice. This is because ceramic abrasive grains are particularly hard and tough. What does this mean specifically? For example, when grinding, every single grain is subjected to cutting forces that act like...

From glass paper to shaped ceramic grain

The first records of the use of sandpaper in England date back to the 18th century. Industrial use as a tool in the form of sandpaper, glass paper or flint paper began with the rapid ongoing industrialisation in Europe and America. Back then, the abrasive material was still attached to the paper backing by means of adhesive. These abrasives therefore performed poorly and they were primarily used for wood and...

Certified and recognized worldwide

The certifications listed here apply to the raw materials produced by our headquarters in Hanover, Germany.

VSM is a member of the Federation of the European Producers of Abrasives (FEPA). The safety standards defined by FEPA ensure the safe use of abrasives.

The Organization for the Safety of Abrasives (oSa) is a voluntary association of abrasive tool manufacturers. VSM is a long-standing member here.

VSM has maintained ISO 9001:2015 certification as the basis for its quality assurance system for many years, ensuring all parts of the company must meet these stringent requirements.

As the largest national association for grinding technology in Europe, the Association of German Abrasive Manufacturers (VDS) represents the interests of VSM as a member of the German abrasives industry.

VSM has been certified as an AEO (Authorized Economic Operator) since 2015. This internationally recognized status guarantees the security of the supply chain from the manufacturer of a product to the end consumer.

We know abrasives – since 1864

2024

Thanks to its innovative, randomised structure, VSM XELERION creates the finest surfaces. The structured abrasive is used for fine and ultra-fine grinding tasks.

2024

On May 28th, 2024, the company turned 160 years old. And it is still located where it was founded, in the heart of Hanover, Germany. VSM has been manufacturing abrasives right from the start.

2023

In November 2023, we commissioned our third Ceramic Grain Production Facility. This means that we are increasing production volumes to ensure our customers worldwide are reliably supplied with VSM ACTIROX and CERAMICS abrasives.

2023

With ALU-X, VSM is introducing an abrasive for aluminium and non-ferrous metals to the market. ALU-X prevents clogging of the abrasive and extends the service life.

2018

VSM ILUMERON makes it possible to grind and polish in a single step. This saves time and reduces production costs.

2018

Developed and produced in Hanover, VSM ACTIROX is a geometrically shaped ceramic grain abrasive for maximum stock removal.

2017

VSM COMPACTGRAIN Plus is introduced to the market and offers a new high level of performance in long-term abrasives.

2015

VSM CERAMICS Plus continues to provide existing CERAMICS abrasives to the market.

2005

Under the brand name CERAMICS, the ceramic grain abrasives manufactured in Hanover are now conquering the global markets.

2004

Start of production of VSM ceramic abrasive grain. This further development of synthetic abrasive grains provides high stock removal with a long service life.

1991

Opening of the Technical Center (TC) training center at the Hanover location. The “1st International Application Seminar” takes place on September 7th, 1992.

1978

VSM COMPACTGRAIN is launched. Today, VSM has one of the most diverse product ranges in the field of long-term abrasives.

1955

Return to the UK. Foundation of the subsidiary VSM Abrasives Ltd. and thus the start of the company’s internationalisation.

1945

By the end of the war, over 85 percent of the factory buildings had been destroyed. Reconstruction of the plant by the employees, without government support.

1930

Specialisation in coated abrasives and machine manufacturing.

1898

Founding of VSM Vereinigte Schmirgel- und Maschinen-Fabriken Aktiengesellschaft. VSM AG still operates in this legal form today.

1890

Establishment of a manufacturing facility in England, UK and introduction of the English brand “Atlas”. The plant was lost in 1918 as a result of the First World War.

1880

Design of the first operational VSM grinding machine for grinding wheels.

1875

The stag beetle was registered as the first trademark.

1864

Company founded in Hanover-Hainholz by Siegmund Oppenheim and Siegmund Seeligmann.

A successful abrasives business for more than 160 years

1864–1898: From company formation to merger

1864 – Company formation

Siegmund Oppenheim and Siegmund Seeligmann form VSM AG. They start producing glass paper by hand in a workshop located in Hanover’s Hainholz district.

1871–1873 – Letters from Director Max Oppenheim

Three original documents from the co-founder.

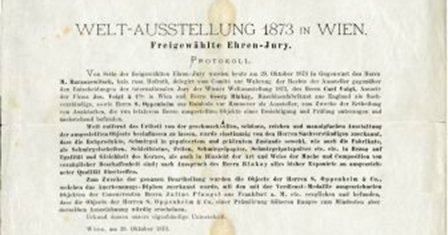

1873 – Quality award at the World Exhibition in Vienna

An award presented at the World Exhibition recognises the outstanding quality of products made by VSM.

1898 Merger

S. Oppenheim & Co. Hainholz and Schlesinger & Co. Harburg merge to become Vereinigte Schmirgel- und Maschinen-Fabriken Aktiengesellschaft.

1900–1945: Boom years and post-war rebuilding

1900 – View from 1900

The VSM factory premises in Hainholz, Hanover.

1914 – 50th anniversary

VSM celebrates its 50th anniversary! The company continues to make record shipments of glass paper and emery cloths.

1924 – Balance sheet

The opening balance sheet from 1924 records a share capital of 3,540,000 gold marks.

1929 – Coming out strong from the global economic crisis

The company now started to specialise in coated abrasives. Hainholz in Hanover became the main site for production.

1932 – Progress

VSM builds its own cloth finishing plant and develops into one of the largest companies in the abrasives industry.

1933 – Vitex

The company registers the ‘Vitex’ trademark, which becomes synonymous internationally for high-performance abrasives.

1943–45 Destruction

During the Second World War, most of the production facilities in Hanover are destroyed.

1945 – Rebuilding

Without needing to draw on state aid, VSM employees rebuild the production facilities with funds from company reserves. Production is already underway again by October 5th, 1945. A brilliant achievement!

1949–1999: Modernisation and internationalisation

1949–1991 – Capacity expansion

An extensive programing of building work is completed during this period, including a new four-story building with laboratories, testing and trial facilities, belt converting lines and storage space, completion of a raw materials warehouse and canteen, construction of a high-bay warehouse, processing jumbo rolls of up to 3,000 linear meters of basic goods.

1955 – UK

Formation of the first subsidiary, VSM Abrasives Ltd. in the UK.

1964 – Centennial anniversary for VSM AG

In the year that VSM AG turns 100, it also posts the best balance sheet result in its history.

1978 – USA

Formation of VSM Abrasives Corporation in the United States of America.

1991 – Training Center

VSM opens its own training center for technical abrasives in Hanover.

1992 – Optimization Phase I

Consolidation of production and new logistics facilities. Foundation of VSM Abrasives Canada Inc. in Oakville and DUNA-VITEX KFT in Budapest, Hungary.

1994 – Optimization Phase II

Introduction of distribution strategy for Germany. Joint ventures are launched with PFERD in both Sweden and Switzerland.

1997 – Joint venture

Start of joint venture with PFERD-VSM in Poland.

1999 – Further expansion

Further expansion of capacities in Hanover plus process optimisation work. An additional converting plant is established in Hungary.

2002 to present day Expansion and extra production capacity

2002 – Construction of new grain facility

Investment of EUR 2 million in a new grain facility.

2004 – Further expansion

Usable space in the packing shop is doubled, plus integration of a new pallet conveyor line. Grand opening of an advanced training center offering professional development for staff and customers, with its own machine room and conferencing systems.

2008 – Production expansion

VSM invests several million euros in new production buildings at the Hanover site.

2012 – Construction of new grain facility

The new grain facility marks the completion of one of the biggest construction projects in VSM’s history.

2018 – Construction of new logistics center

After one year of construction, VSM has been able to surpass itself once again with the construction of a new state-of-the-art logistics center – the company’s largest single project in its 154-year history.

Language selection

Please select your preferred language

VSM USA

1012 East Wabash St.

O’Fallon, MO 63366

Contact

Find your local contact

Let’s get started!

We use cookies to offer you the best possible usage experience on our website. By default, we only use essential cookies. We only use functional and statistical cookies with your consent. You can withdraw this consent at any time with effect for the future in the Cookie Manager or in the data protection declaration. Further processing of data already collected by third parties before the consent is withdrawn cannot be ruled out. If the cookies are rejected, you may not be able to use all functions of the website.

Data protection declaration

This privacy policy provides users of our service with information about the type, scope and purpose of our collection and use of personal data. ‘Personal data’ means any information relating to an identified or identifiable natural person.

We treat your personal data confidentially, and in accordance with data protection laws and regulations, as well as this privacy policy. Personal data is collected, processed and used only if you have consented to this activity or if such an activity is permitted by law. We employ appropriate technical and organisational measures to ensure data protection and data security, and to keep personal data collection to a minimum.

We maintain our privacy policy at https://us.vsmabrasives.com/data-protection/, from where it can be viewed, downloaded and printed out at any time.

Accordingly, complete protection against access by third parties is not possible. We use technical and organisational measures to protect our website and other systems against the loss, destruction, access, modification and distribution of your data by unauthorised persons. Despite regular checks, however, it is not possible to provide complete protection against all risks.

Certain parts of this website utilise the industry standard SSL (Secure Sockets Layer). This ensures the confidentiality of your personal information as sent via the internet. A closed key or lock symbol in the lower status bar of your browser shows you if an individual page of our website is being transmitted in an encrypted format.

We would like to remind you that data transmission via the internet (e.g. communication by email) can entail security risks.

I. Name and address of the data processing controller

Controller for data processing within the meaning of the General Data Protection Regulation (GDPR), other data protection laws applicable in Member States of the European Union and other provisions related to data protection:

VSM · Vereinigte Schmirgel- und Maschinen-Fabriken AG

Siegmundstrasse 17

30165 Hanover, Germany

Tel.: +49 511 3526-0

F +49 511 3521 315

info@vsmabrasives.com

www.vsmabrasives.com

II. Name and address of the Data Protection Officer

Data Protection Officer and data processing controller:

Thomas Spaeing

ds² Unternehmensberatung GmbH & Co. KG

Falkenstraße 10

33775 Versmold, Germany

T +49 5423 95 99 320

datenschutzbeauftragter@vsmabrasives.com

Any affected individual (= ‘data subject’) is welcome to direct their enquiries or feedback to our Data Protection Officer at any time.

III. Provision of the website and creation of server log files

1. Hosting

We use the following hosts to make our website available:

webgo GmbH

Heidenkampsweg 81

20097 Hamburg, Germany

T +49 40 605 900 399

support@webgo.de

An order processing agreement has been concluded with WebGo GmbH pursuant to Art. 28 GDPR. The legal basis is our legitimate interest within the meaning of Article 6(1)(1)(f) GDPR in the operation and maintenance of the operational security of these websites. The server location is Germany.

2. Description and scope of data processing

Each time our website is accessed, our system automatically collects data and information from the computer system of the accessing computer. The following data is collected:

- Referrer (previously visited website)

- Requested website or file

- Browser type and version

- Operating system used

- Device type used

- Time of access

- IP address in anonymized form (only used to determine the access location)

The data is also stored in the log files of our system. This data is not stored together with other personal data of the user.

3. Legal basis for data processing

The legal basis for the temporary storage of data and log files is Art. 6(1)(f) GDPR. The provision of personal data is in part in our legitimate interest, and the provision of this data is partly required by law (see point 5, second paragraph). Not providing the data is not an option.

4. Purpose of the data processing

The temporary storage of the IP address by the system is necessary in order to enable the website to be delivered to the user’s computer. For this purpose, the IP address of the user must remain stored for the duration of the session.

The data is stored in log files in order to ensure the functionality of the website. We also use the data to optimise the website and to guarantee the security of our IT systems. We also have a legitimate interest in this data processing in accordance with Article 6(1)(f) GDPR. The data is not evaluated for marketing purposes in this context.

5. Categories of recipients of personal data and data processing outside the European Union

We do not pass on personal data to third parties unless we are obliged to do so by law or we have given consent to do so.

This does not include the involvement of service providers, e.g. for the hosting of the website, which we carefully select in particular with regard to data protection and security of the data and for which we have taken all measures required under data protection law for permissible data processing. Data is not processed outside the European Union.

6. Duration of storage

The data is deleted as soon as it is no longer required to achieve the purpose for which it was collected. For data collected for the provision of the website, this is deleted when the respective session has ended, or within a maximum of seven days.

7. Possibility of objection and elimination

The collection of data for the provision of the website and the storage of data in log files is essential for the operation of the website. Consequently, the user has no right to object.

IV. Content delivery network (CDN)

We use the Content Delivery Network (CDN) of Cloudflare Germany GmbH, Rosental 7, c/o Mindspace, 80331 Munich Germany (Cloudflare) to increase the security and delivery speed of our website. A CDN is a network of (globally) distributed servers that is able to deliver optimised content to the website user. Personal data may be processed in Cloudflare server log files for this purpose.

Cloudflare is the recipient of your personal data and acts as a processor for us. This corresponds to our legitimate interest within the meaning of Article 6(1)(1)(f) GDPR, not to operate a Content Delivery Network ourself and to have the page displayed in a fault-free and optimised manner.

You have the right to object to this processing. Whether the objection is successful must be determined in the context of a balance of interests.

Your personal data will be stored by Cloudflare for as long as necessary for the purposes described.

You can find more information on the options for objection and elimination relating to Cloudflare at: https://www.cloudflare.com/gdpr/introduction/

We have concluded a corresponding agreement on order processing or standard contractual clauses with Cloudflare on the basis of GDPR. The data is processed in Germany or countries within the European Union. If processing takes place in third countries in certain cases, processing shall only take place if the level of data protection in the third country has been deemed by the EU Commission to be adequate in accordance with Article 45 GDPR, on the basis of the EU standard contractual clauses or if an adequate level of data protection is ensured by the data recipient in another way.

More information is available at: https://www.cloudflare.com/cloudflare-customer-dpa/

V. Cookies

We use services of etracker GmbH from Hamburg, Germany for analysing usage data. We do not use cookies for web analysis by default. If we use analysis and optimisation cookies, we will obtain your explicit consent separately in advance. If this is the case and you agree, cookies are used that enable a statistical reach analysis of this website, a measurement of the success of our online marketing measures and test procedures, in order to test and optimise different versions of our online service or its components, for example. Cookies are small text files that are stored by the Internet browser on the user’s end device. etracker cookies do not contain any information that enables a user to be identified.

The data generated with etracker is processed and stored by etracker exclusively in Germany. etracker has been assessed by an independent body in this respect, certified and awarded the privacy seal ePrivacyseal

The legal basis for the data processing is Art. 6(1)(f) GDPR. Our legitimate interest is the optimisation of our online service and our website. The data that may be attributable to a specific individual, such as the IP address, login or device identifiers, is anonymized or pseudonymized as soon as possible. No other use, combination with other data or disclosure to third parties takes place.<br>

You can object to the aforementioned data processing at any time. The objection has no adverse consequences.

Further information on data protection at etracker is available here: https://www.etracker.com/en/data-privacy/

VI. E-mail contact and contact form

1. Description and scope of data processing

You can contact us on our website using the e-mail address or contact form provided. In this case, the personal data of the user transmitted with the e-mail or form is stored. Other personal data will be collected only if the user consents to this collection in accordance with applicable regulations or there is a legal basis for such collection. We use this personal data to answer the user’s enquiries, to process contracts concluded with the user and for any technical administration purposes that may be necessary.

In this context – with the exception of the purposes of fulfilling the contract, cf. Clause 8 – no transfer of data to third parties takes place. The data is used exclusively for communication with the user.

2. Legal basis for data processing

Data processing for the purpose of making contact is carried out based on point (a) of Art. 6(1) GDPR and your freely given consent. The legal basis for the processing of data transmitted in the course of sending an e-mail or using the contact form is also Art. 6(1)(f) GDPR to enable us to contact you. If the contact is aimed at concluding a contract, an additional legal basis for processing is Art. 6(1)(b) GDPR.

3. Purpose of the data processing

Personal data is processed solely for the purpose of processing the contact.

4. Categories of recipients of personal data and data processing outside the European Union

We do not pass on personal data to third parties unless we are obliged to do so by law or we have given consent to do so. Exceptions to this are the involvement of the service provider, which enables hosting of the website. Data is not processed outside the European Union.

5. Duration of storage

The data is deleted as soon as it is no longer required to achieve the purpose for which it was collected. For the personal data sent by e-mail or contact form, this is when the respective conversation with the user has ended.

The conversation ends when it can be concluded from the circumstances that the matter in question has been clarified. Further retention periods may arise from the German Fiscal Code or the German Commercial Code.

6. Possibility of objection and elimination

If the user contacts us by e-mail, they can object to the storage of their personal data at any time. If the user objects, the conversation cannot be continued. In this case, all personal data stored in the course of contacting us will be deleted, unless statutory retention periods prevent this.

VII. Career / job portal

In our Careers section, you can use our online form to apply for advertised vacancies or submit a speculative application. For this purpose, we use the applicant platform rexx systems (https://www.rexx-systems.com/), which is operated by rexx systems GmbH, Süderstrasse 75–79, 20097 Hamburg, Germany. This is an online platform for handling job applications. When you access the Careers section on our website, the link integrated in this page establishes a connection to rexx systems in order to enable the technical transfer of the application documents. Data is transferred to rexx systems when this connection to rexx systems is made. On any visit to the rexx systems website, rexx systems will normally save the IP address as assigned to you by your internet service provider (ISP). Personal data that we exclusively for the purpose of processing your application will only be stored if you provide us with this data yourself in the context of your application. In this case, the information is entered either voluntarily or, where indicated with an asterisk (*), as required information. We require these fields to be completed so that we can process your application and stay in contact during the application process. Your digital candidate file contains all of the data you entered as a candidate as well as our entire contact history. The data is processed exclusively for the purpose of processing the application in line with point (a) of Art. 6(1) GDPR, based on your freely given consent, or for making a decision to establish an employment relationship in accordance with section 26(1) sent. 1 of the German Data Protection Act (BDSG). The personal data that we collect from the completed form as well as the other files you upload to us will be stored for 6 months after completion of the application process (rejection or employment) and then erased.

VIII. Webinars

For webinars, we use WebinarGeek.com’s webinar platform (Chroomstraat 12, 2718 RR Zoetermeer, The Netherlands).

In order to log in to and carry out the online seminars, we use the data you provide to us when registering for the respective seminar, namely first name, surname, e-mail, company/employer and postcode.

After registration, we will use your e-mail address to confirm registration, send dial-in information and remind you of the upcoming event shortly before the webinar. After a webinar, we will use your e-mail address and name once to send you an e-mail and give you access to the recordings of the online seminar.

We will receive the following data from you as part of the online seminar: Surname, first name, e-mail address for identification and login, country, IP address and cookies to manage the web session and ensure the provision of the webinar. Your data will only be processed as part of the online seminar.

The legal basis for the aforementioned data processing is Art. 6(1)(b) GDPR. The processing is solely for the purpose of fulfilling the contract in the form of the execution as well as preparation and follow-up of the participation agreement for the respective webinar.

An order processing agreement has been concluded with Webinargeek. Webinargeek processes the data exclusively in the European Union. Your personal data will not be transferred to third countries.

Further information on data protection at Webinargeek can be found at: https://www.webinargeek.com/privacy

IX. Forwarding of data

Your personal data will not be shared with third parties for any reason except the purposes as listed below. We share your personal data with third parties in the following cases:

- If you have given your express consent pursuant to point (a) of Art. 6(1) GDPR, such a transfer in accordance with point (f) of Art. 6(1) GDPR is necessary for the establishment, exercising or defence of legal claims, and there is no reason to assume that you have an overriding legitimate interest in not having your data shared in this way

- In cases where there is a legal obligation to share the data pursuant to point (c) of Art. 6(1) GDPR

- Transfer is legally permissible and is also required for processing contractual relationships with you pursuant to point (b) of Art. 6(1) GDPR

X. Rights of the Data Subject

You are granted the following rights:

- Pursuant to Art. 15 GDPR, the right to request information about the type and scope of the personal data we collect, in particular its processing, planned retention period, continuation and disclosure

- Pursuant to Art. 16 GDPR, the right to demand the immediate rectification of your personal data that is stored by us if this data is incorrect or incomplete

- Pursuant to Art. 17 GDPR, the right to demand the erasure of your personal data stored with us, unless the processing of this data is necessary to exercise the right to freedom of expression and information, to fulfil a legal obligation, for reasons of public interest, or to establish, exercise or defend legal claims; or alternatively, pursuant to Art. 18 GDPR, you have the right to demand that the processing of the data be restricted

- Pursuant to Art. 20 GDPR, the right to receive your personal data and to demand its transfer to other controllers

- Pursuant to Art. 7(3) GDPR, the right to withdraw your consent as given to us at any time As a result of this withdrawal of consent, we will no longer be allowed to continue the data processing that was based on this consent.

- Pursuant to Art. 77 GDPR, the right to lodge a complaint with a supervisory authority. The normal procedure here is to contact the state supervisory authority.

- On the basis of GDPR Art. 21, you have the right to object, on grounds relating to your particular situation, at any time to processing of personal data about you, where such processing is based on point (e) or (f) of Art. 6(1) of the GDPR.

XI. Social media services

1. Xing

We operate a presence on the social career network Xing (hereinafter referred to as "Xing"), which is operated exclusively by New Work SE, Am Strandkai 1, 20457 Hamburg. The reference is identified by the Xing logo (no Xing plug-in). When you click on a Xing link, your browser establishes a direct connection with Xing’s servers. If you are already logged in to Xing via your personal user account, the information about your visit to our website is automatically forwarded to LinkedIn. It is then possible for Xing to assign the visit to the website to your account. We would like to point out that we do not receive any knowledge of the content of the transmitted data or its use by Xing.

If you want to prevent this transfer and storage of data about you and your usage of our website by Xing, then you must log out of your personal Xing account before your visit our website.

For further information, please refer to the Xing Data Protection, Terms of Use and Terms and Conditions, in particular at https://privacy.xing.com/en

2. LinkedIn

We operate a presence on the social career network LinkedIn, hereinafter referred to as "LinkedIn"), LinkedIn Ireland Unlimited Company, Wilton Plaza, Wilton Place, Dublin 2, Ireland. which is exclusively owned by LinkedIn Corporation (2029 Stierlin Court, Mountain View, CA 94043, USA; hereinafter: "LinkedIn"). The reference is identified by the LinkedIn logo (no LinkedIn plug-in). When you click on a LinkedIn link, your browser establishes a direct connection with LinkedIn’s servers. If you are already logged in to LinkedIn via your personal user account, the information about your visit to our website is automatically forwarded to LinkedIn. It is then possible for LinkedIn to assign the visit to the website to your account. We would like to point out that we do not receive any knowledge of the content of the transmitted data or its use by LinkedIn.

If you want to prevent this transfer and storage of data about you and your usage of our website by LinkedIn, then you must log out of your personal LinkedIn account before your visit our website.

For further information, please refer to LinkedIn’s terms of use and general terms and conditions, available at https://www.linkedin.com/legal/privacy-policy?

3. YouTube

We have integrated YouTube videos into our website. These videos are stored at http://www.YouTube.com and can be played directly from our website. The videos are all embedded in "enhanced privacy mode", which means that if you do not play the videos, no data about you as a user will be transferred to YouTube. Only when you play the videos will personal data be transferred. We have no control over this data transfer. It is possible that your data on YouTube or Google may be transferred to the USA and thus to an unsecure third country under data protection law. Unsecure third countries do not offer a level of data protection comparable to EU standards. No other guarantees are offered to compensate for this deficit. There is a risk that the transfer could result in government bodies accessing your data without you having effective legal protection

If you are logged in to Google, your data will be directly associated with your account. If you do not wish the data to be associated with your YouTube profile, you must log out before activating the button. YouTube stores your data as user profiles and uses it for the purposes of advertising, market research and/or the needs-based design of its website. Such evaluations are carried out (even for users who are not logged in) in particular to deliver needs-based advertising and to inform other users of the social network about your activities on our website. You have the right to object to these user profiles being created. To exercise this right, you must contact YouTube.

For more information on the purpose and scope of data collection and processing by YouTube, please see the relevant privacy policy. The policy also provides you with further information about your rights and about the settings you can adjust in order to protect your privacy: https://policies.google.com/privacy?hl=en&gl=de.

Essential cookies are always activated because they are required for the operation of the website and for storing your cookie consent, for example, by enabling navigation and access to secure areas of the website. Without these cookies, the website cannot function properly.

Protects against cross-site request forgery attacks.

Saves the current PHP session.

We use third-party cookies to provide external media. When our videos are played, data is transferred to YouTube or Google and thus potentially to a third country that is unsecure under data protection law. You can find more information on transmission to third countries in our data protection declaration.

Statistical cookies are used to assess how you use our website, e.g. how you move around the page, which pages you visit the most. The information helps us to improve the user-friendliness and quality of our website. We use the services of eTracker GmbH for web analysis. You can find information on this in our data protection declaration.

Google Analytics enables the website operator to analyze the behavior of website visitors.